Non-Storage Calorifiers: Instantaneous & Efficient Hot Water

World Heat Cylinders designs and manufactures a versatile range of Non-Storage Calorifiers. These are often referred to as shell and tube heat exchangers. Essentially, these units are engineered to heat a fluid, typically water, instantaneously as it passes through the heat exchanger. Consequently, they provide an on-demand hot water solution. This approach avoids the need for a stored volume of heated water within the unit itself, thus making them highly efficient for specific applications.

Furthermore, our non-storage calorifiers ensure rapid heat transfer. This makes them ideal for processes requiring immediate hot water or for systems with consistent, high-volume demands.

How Our Non-Storage Calorifiers Work

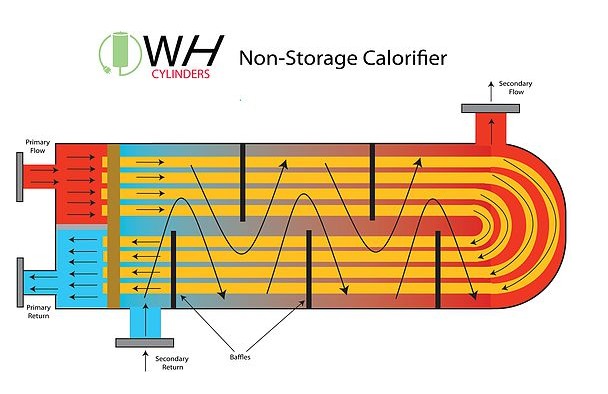

The core of our non-storage calorifiers typically incorporates a multi-purpose heat exchanger. This is usually a removable U-tube battery. Such a design allows the primary heating medium (like LTHW from a boiler, or steam) to pass through the tubes. As this medium flows to the end of the exchanger and then back again, it efficiently transfers its heat. The heat moves to the secondary fluid (e.g., domestic hot water, pool water) which passes over the exterior of the tubes within the main shell.

Key design aspects, for instance, include:

- Instantaneous Heating: The system heats fluid on demand as it flows through the unit.

- Efficient Heat Transfer: The U-tube design, moreover, maximises the surface area available for heat exchange. This promotes rapid and efficient energy transfer.

- Shell and Tube Construction: This robust design is, indeed, well-suited for various commercial and industrial applications.

Materials, Construction & Insulation

We typically manufacture our heat exchanger shells from robust mild steel. For optimal thermal conductivity and durability, the primary heat exchange tubes are often copper or copper-alloy (like integron tubes), which are then expanded into a steel or brass tube plate. However, our expert fabricators can also construct these units with stainless steel shells. Additionally, stainless steel tubes can be used for applications requiring higher corrosion resistance or specific process compatibility. It is always best to discuss your fluid types with our engineers.

Furthermore, WH Cylinders offers various insulation methods for all our non-storage calorifiers. These are designed to suit your exact requirements, thereby minimising heat loss and ensuring efficient operation. Indeed, options range from basic insulation to high-density injected polyurethane foam complete with durable outer casings.

Benefits & Applications of Non-Storage Calorifiers

A major benefit of a non-storage calorifier, when compared to some other types of heat exchangers like certain plate heat exchangers, is its comparatively low pressure drop. This means less resistance on the secondary fluid side. Such a characteristic, therefore, makes these units ideal for heating fluids at higher flow rates.

Typical applications, for example, include:

- Swimming pool heating systems.

- Large domestic hot water circuits that have consistent demand.

- Various industrial process heating requirements.

- Steam-to-water applications: These units efficiently provide a large amount of hot water with a relatively small temperature increase, often around 11°C per pass with steam. Consequently, this makes them suitable for steam boilers in large commercial plants. Such plants may require reduced water temperatures before the water enters a radiator circuit. Notably, WH Cylinders’ steam-to-water calorifiers can also include an attached condensate unit, which maximises heat usage and boosts efficiency.

It is important to clarify a point from older descriptions. The terms “single feed Indirect cylinder” and “cold water header tank” typically describe a traditional vented *storage* cylinder system. This operation is different from these non-storage calorifiers, which heat water instantaneously as it passes through. They do not use a primary circuit to heat a stored body of potable water fed by a header tank.

Bespoke Design & Technical Support

Our expert design engineers can specify and supply the correct non-storage heat exchanger to suit your unique application. As we manufacture these units in many different shapes, sizes, and materials (steel or stainless steel for the shell), we can tailor a solution for your requirements. If you have specific needs outside of our standard product range, please do not hesitate to contact our technical design engineers for assistance.

Enquire About Non-Storage Calorifiers

Please feel free to contact one of our experienced design engineers with any questions or to discuss your Non-Storage Calorifier application. We can assist in specifying and supplying the correct heat exchanger for your needs.

Call us on 0161 343 8610 or email sales@whcylinders.co.uk.