Plate Heat Exchangers (PHEs)

World Heat Cylinders offers a comprehensive range of both Gasketed Plate Heat Exchangers (GPHE) and Brazed Plate Heat Exchangers (BPHE). Plate Heat Exchangers, often called PHEs, provide an extremely efficient and compact way to transfer heat between two separate fluids. Furthermore, PHEs present several distinct advantages over traditional shell and tube heat exchangers. Consequently, they are a preferred choice for many industrial and commercial applications.

Key benefits of our Plate Heat Exchanger solutions include:

- Superior Thermal Efficiency: The plate design creates turbulent flow. This turbulence maximises heat transfer coefficients.

- Compact Footprint: PHEs typically need much less space than shell and tube units of equivalent thermal capacity.

- Flexibility and Modularity (Gasketed): Users can easily modify Gasketed PHEs by adding or removing plates. This adjusts capacity or accommodates changing process requirements.

- Ease of Maintenance (Gasketed): Gasketed units allow opening for inspection and cleaning. Gasket and plate replacement is also straightforward.

- Resistance to Scaling and Fouling: High flow rates and turbulent flow effectively help to minimise fouling and scaling. This leads to longer operational periods between cleaning.

Gasketed Plate Heat Exchangers (GPHE)

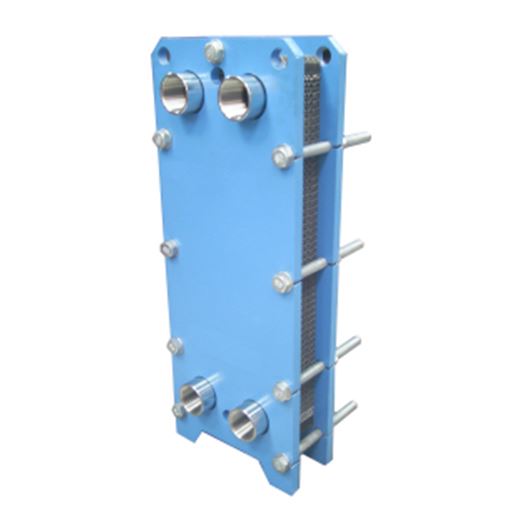

Gasketed Plate Heat Exchangers (GPHEs) from World Heat Cylinders are robustly constructed, ensuring reliable performance and easy servicing. Typically, they consist of three primary components:

- Corrugated Plates: A series of pressed, corrugated stainless steel plates are precisely arranged. This arrangement creates a honeycomb-like pattern of flow channels. A durable gasket seals each plate, forming the complete plate pack.

- Frame Plates: The design securely sandwiches the plate pack between two sturdy carbon steel frame plates. These are a fixed frame plate and a movable pressure plate.

- Tightening Bolts: These bolts compress the plate pack and frame plates together. This action ensures a leak-tight seal. Additionally, depending on the unit’s overall size, a carrier bar may be included. The carrier bar supports the plate pack and facilitates easier maintenance and plate replacement.

Moreover, our Gasketed PHEs suit a wide range of duties. We can tailor them with various plate materials, gasket types, and frame designs to meet specific process conditions.

Brazed Plate Heat Exchangers (BPHE)

Brazed Plate Heat Exchangers (BPHEs) provide an extremely compact and cost-effective solution for heat transfer. These units feature a metallic plate pack, usually stainless steel, sandwiched between a front and a rear cover plate. Unlike gasketed versions, BPHEs do not include gaskets. Instead, a specialised vacuum furnace permanently joins the plates using a brazing material, typically pure copper.

Key characteristics of World Heat Brazed Plate Heat Exchangers include:

- Exceptional Compactness: The brazed construction results in a very small footprint for a given thermal duty. Therefore, they are excellent for tight spaces.

- High Pressure & Temperature Capability: Generally, BPHEs can withstand higher operating pressures and temperatures than standard gasketed units. This is due to their robust, sealed construction.

- Cost-Effectiveness: BPHEs are often a more economical choice for standard applications, especially where frequent disassembly is not necessary.

- Leak Resistance: The brazed design offers excellent integrity against leaks, ensuring system reliability.

Consequently, BPHEs are ideal for applications such as refrigerant systems and hydraulic oil cooling. They are also excellent for domestic hot water generation where a compact, maintenance-free unit is desired.

PHE Accessories

To complement our Gasketed and Brazed Plate Heat Exchangers, World Heat Cylinders offers a range of practical accessories. These accessories are designed to enhance performance, improve safety, and simplify maintenance.

- Insulation Jackets: We provide bespoke-fit insulation jackets for both Gasketed and Brazed PHEs. These high-quality jackets effectively minimise heat loss or prevent condensation. They are filled with appropriate insulation material and feature a Velcro fastening system, which allows for easy removal and re-fitting.

- Splash Guards: For applications where personnel might risk contact with hot surfaces or potential spray, we offer stainless steel splash guards. These guards protect operators from the plate pack’s hot and potentially sharp surfaces.

- Drip Trays: We can supply stainless steel drip trays to effectively collect any fluid medium from a Gasketed Plate Heat Exchanger. This is particularly useful during routine maintenance, such as dismantling for cleaning or draining the unit. Thus, it helps maintain a clean and safe working environment.

Bespoke Plate Heat Exchanger Packages

World Heat Cylinders excels in providing bespoke Plate Heat Exchanger Packages. We fully engineer and assemble these packages to meet the demands of diverse applications. Furthermore, these packaged solutions simplify on-site installation and ensure optimal system integration. Common applications include:

- Domestic Hot Water (DHW) generation

- Low-Temperature Hot Water (LTHW) systems

- Medium-Temperature Hot Water (MTHW) systems

- Steam-to-water applications

- Various industrial process heating and cooling duties

Our PHE packages can incorporate a multitude of components, configured to suit your client’s specific operational requirements. For example, these pre-assembled modules can include:

- Storage Vessels or Buffer Vessels (e.g., for DHW packages, see our buffer vessel range)

- Primary and secondary circuit pumps

- Control valves, sensors, and comprehensive control panels

- Unvented system kits (where applicable)

- Pipework, insulation, and mounting frames

By opting for a packaged PHE system, you therefore benefit from reduced design time, faster installation, and a single point of responsibility for the core heating or cooling interface.

If you have any queries or enquiries, please contact our technical sales team. Feel free to call on 0161 343 8610 or email sales@whcylinders.co.uk.