Steam System Vent Heads

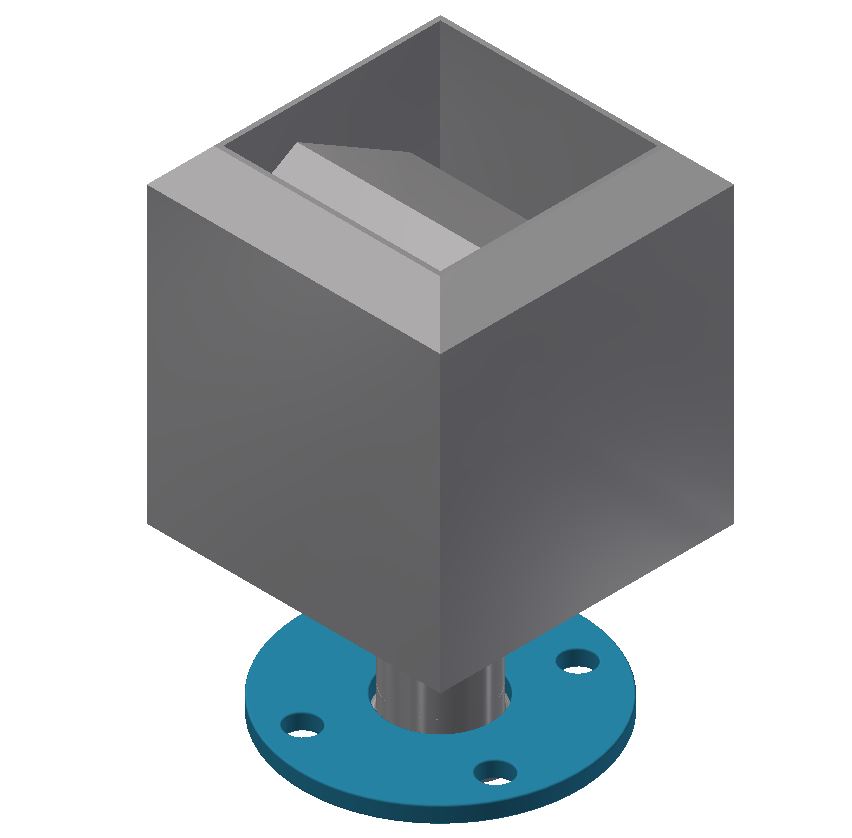

World Heat Cylinders designs and manufactures a robust range of Steam Vent Heads, essential safety components for various industrial and commercial steam systems. These units are specifically engineered for installation on vertical open-ended steam vent pipes. You will commonly find such pipes on equipment like Blowdown Vessels, Boiler Feed Tanks, De-aerator Heads, and Condensate Vessels. The primary purpose of a Vent Head is critical: it efficiently removes entrained water (moisture) from discharge steam. Consequently, this ensures the safe release of substantially dry steam into the atmosphere, protecting personnel and ancillary equipment.

Operating Principle & Key Design Features

Our Steam Vent Heads operate on a proven principle to ensure effective moisture separation:

- Steam Inlet: Steam, carrying entrained water droplets, enters the Vent Head through the main inlet connection at the base.

- Internal Baffle System: The incoming steam is then directed towards an internal baffle arrangement. This strategically designed baffle causes an abrupt change in flow direction.

- Moisture Separation: As the steam impacts the baffle and changes direction, the heavier water droplets lose momentum. They impinge and collect on the internal surfaces of the Vent Head.

- Condensate Collection & Drainage: Due to gravitational forces, the entrained water coalesces into larger droplets. These then collect at the bottom of the Vent Head unit. From here, the condensate makes its way out, typically through a dedicated drain connection.

- Dry Steam Discharge: The significantly drier steam, now largely free of entrained liquid, exits safely to the atmosphere through the top outlet of the Vent Head.

A key feature of many World Heat Vent Head designs is an internal drain. This allows the recovered condensate to be efficiently fed back into the boiler feedwater system or another suitable point. This condensate recovery not only prevents wastage but also significantly increases the overall energy efficiency of the steam system by reclaiming valuable hot water.

Benefits of WH Cylinders Steam Vent Heads

- Enhanced Safety: Prevents the hazardous discharge of wet steam or slugs of hot water, protecting personnel and nearby equipment.

- Improved Energy Efficiency: Condensate recovery options allow for the reuse of valuable heat energy, reducing fuel consumption.

- Equipment Protection: Reduces potential erosion or damage to downstream pipework and components caused by wet steam.

- Reduced Water Hammer: Minimises the risk of water hammer in steam lines by removing entrained moisture.

- Durable Construction: Manufactured from robust materials suitable for steam applications, ensuring a long service life.

- Bespoke Design Options: We can tailor vent head sizes, connection types, and materials to suit specific system parameters and flow rates.

Applications & Sizing Considerations

World Heat Steam Vent Heads are suitable for a wide range of applications where steam is vented to the atmosphere, including:

- Boiler Blowdown Systems

- Boiler Feed Tanks & De-aerators

- Condensate Receiver Tanks

- Steam Process Vessels

- Flash Steam Recovery Systems

Correct sizing of the Vent Head is crucial for effective operation. It depends on factors such as steam flow rate, operating pressure, and the amount of entrained moisture expected. Our technical sales team can assist you in selecting or designing the appropriately sized Vent Head for your specific application to ensure optimal performance and safety.

Technical Specifications & Enquiries

For detailed technical specifications of our standard Steam Vent Heads, including dimensions and material options, please download our product information sheet:

If you require a bespoke Vent Head design, have specific application queries, or wish to discuss your project with our experts, please do not hesitate to contact us. We are committed to providing effective solutions for your steam system needs.

Call our technical sales team on 0161 343 8610 or email sales@whcylinders.co.uk for assistance. You can also use our contact page.